Die creasing

General information

Extreme precision for a clean fold with no cracks.

Die creasing is essential for achieving a sharp, professional fold, especially with heavyweight boards, laminated brochures, or photographic paper.

This technique uses the same blade-and-matrix system found in die-cutting machines, delivering exceptional accuracy and consistency. Unlike traditional scoring, die creasing produces clean, crack-free results across a variety of paper types, finishes, and fibres – with minimal setup and excellent repeatability.

During the process, the material is precisely aligned before the creasing blade presses it into a matrix. The depth and width of the crease can be fine-tuned by repeating the process or adjusting in decimal increments.

The same die-based mechanical technology also enables both continuous and step perforations – ideal for tear lines, detachable sections, or “coupon-style” finishes.

Machines

Our die creasing & perforating machines

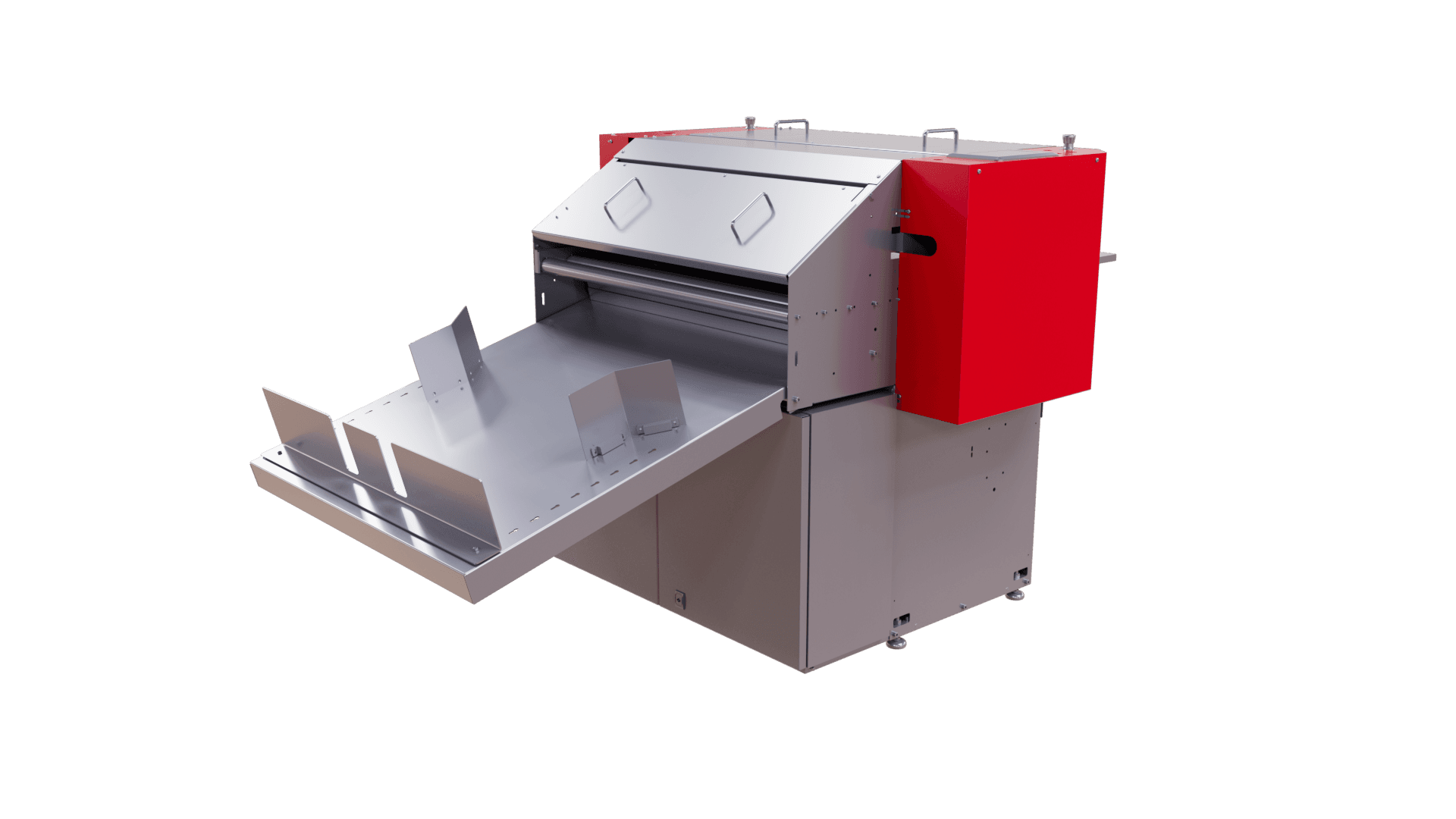

BAT Pile

Creasing solution for paper and cardboard from 80 to 600 gsm.

NEW

Eclipse Junior

Perfect die-cutting without dies: the new Eclipse Junior delivers flawless results and cost-effectiveness on short and medium runs.

NEW

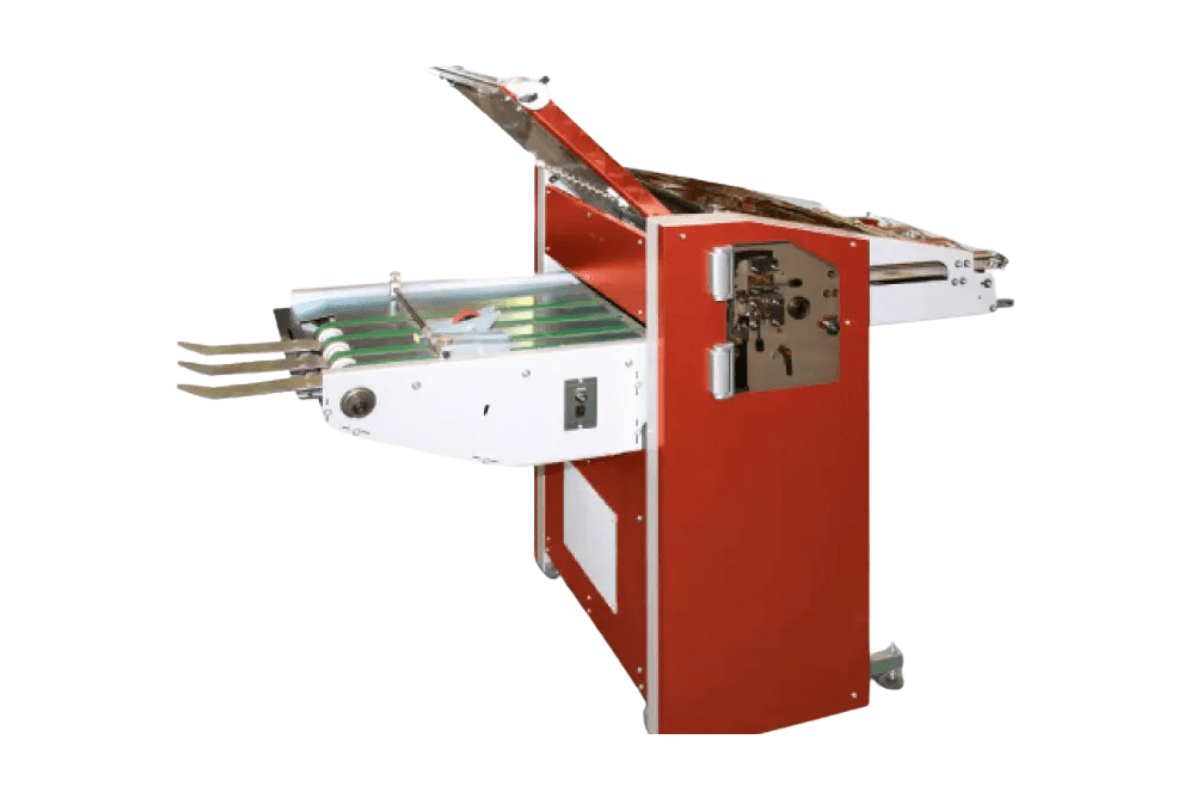

Cordoba 4

The new Cordoba 4 creases, folds and glues a wide range of paper and cardboard products (60-800 g).

Machines

Quality accessories for any setup

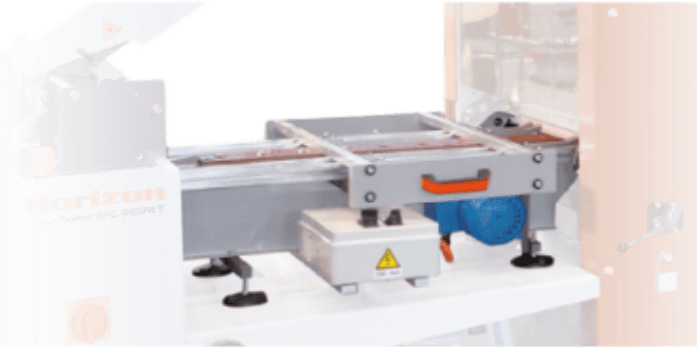

Motor-driven table BJC

An independent powered unit that transports creased sheets directly into the first folding group’s side lay – bypassing the pile feeder.

Format: Max. 60 cm - Min. 14 x 10 cm

BA 50 Folding Group

Designed for lightweight or photographic paper, BA 50 uses large-diameter rollers (Ø 7 cm) and a top buckle plate to create smooth, consistent folds. Two pressing rollers flatten the fold for perfect packaging.

Can be used in-line with Mini BAT Plus.

PGN TP46-66 Folding Group

Ideal for 200–600 gsm paper or cardboard, such as calendar bases. The upper buckle plate and pressing rollers ensure even, flawless folds.

Can be used in-line with Mini BAT Plus.